In the realm of automotive engineering, “tranny tubes” play a critical role in ensuring the smooth operation and efficiency of transmission systems. This comprehensive article aims to delve deep into the world of tranny tubes, surpassing existing online sources by providing unique interpretations, analyses, and insights.

Designed to cater to automotive enthusiasts and professionals in the USA, our exploration will cover everything from the origins and types of tranny tubes to their applications, benefits, and future trends.

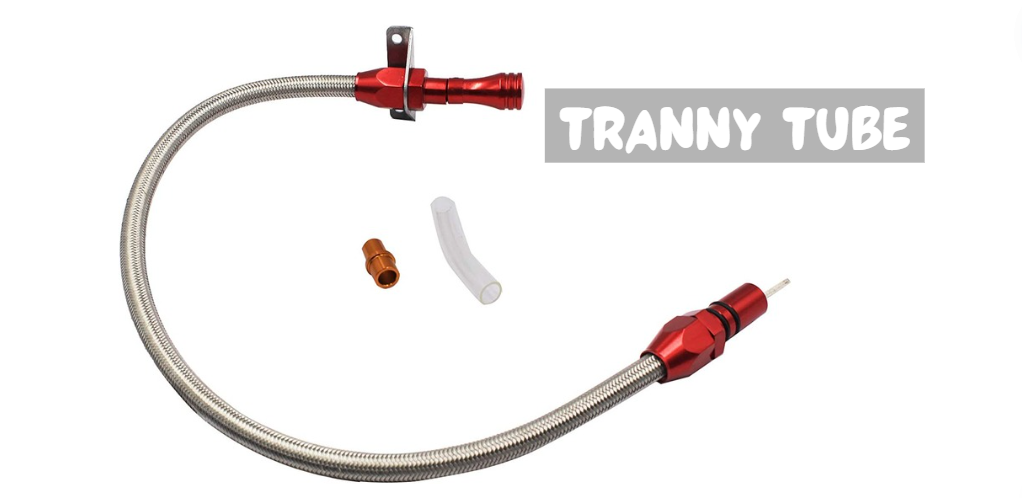

Introduction to Tranny Tubes

Tranny tubes, short for transmission tubes, are integral components within the transmission systems of vehicles. These tubes are designed to facilitate the flow of transmission fluids, ensuring optimal performance and longevity of the transmission assembly.

Origins and Evolution

The development of tranny tubes parallels advancements in automotive technology, dating back to the early 20th century when internal combustion engines became mainstream. Initially simple in design, tranny tubes have evolved significantly over the decades, driven by innovations in materials and manufacturing processes.

Types and Varieties

Tranny tubes come in various types and configurations, each tailored to specific needs within the transmission system.

Transmission Cooler Tubes

Transmission cooler tubes are crucial for maintaining the optimal temperature of transmission fluid, preventing overheating and ensuring efficient operation.

Breather Tubes

Breather tubes allow for the release of excess pressure within the transmission system, safeguarding against damage and ensuring consistent performance.

Customized Designs

Custom tranny tubes are tailored to unique specifications, often used in performance vehicles or specialized applications where standard designs may not suffice.

Applications in Automotive Systems

Tranny tubes are indispensable in modern automotive systems, serving multiple functions that contribute to vehicle performance and reliability.

Role in Transmission Systems

Within the transmission system, tranny tubes manage fluid circulation, cooling, and pressure regulation, essential for smooth gear shifts and overall drivability.

Performance Enhancements

In high-performance vehicles and racing cars, customized tranny tubes are employed to enhance fluid dynamics and heat dissipation, optimizing power delivery and efficiency.

Benefits of Tranny Tubes

Using high-quality tranny tubes offers several benefits that contribute to the efficiency and longevity of automotive transmission systems.

Enhanced Cooling Efficiency

Transmission cooler tubes improve heat dissipation, preventing fluid degradation and extending the lifespan of transmission components.

Improved Fluid Management

Tranny tubes facilitate precise fluid circulation and pressure control, minimizing wear on gears and bearings for sustained performance.

Durability and Reliability

Well-designed tranny tubes enhance the durability of transmission systems, reducing the risk of overheating and mechanical failures during operation.

Choosing the Right Tranny Tube

Selecting the appropriate tranny tube involves considering factors such as material composition, compatibility, and performance requirements.

Material Selection

Optimal materials for tranny tubes include aluminum alloys and high-grade plastics, chosen for their thermal conductivity and resistance to corrosion.

Compatibility Considerations

Ensure the tranny tube matches the specifications of your vehicle’s transmission system, including size, fittings, and pressure ratings.

Performance Enhancements

For enthusiasts and professionals seeking performance gains, custom tranny tubes offer tailored solutions that enhance fluid dynamics and thermal management.

Installation and Maintenance

Proper installation and regular maintenance are crucial for maximizing the lifespan and performance of tranny tubes.

Installation Best Practices

Follow manufacturer guidelines for installation, ensuring secure fittings and proper alignment within the transmission assembly.

Routine Maintenance

Regularly inspect tranny tubes for leaks, corrosion, or damage, and schedule periodic fluid changes to maintain optimal transmission performance.

Common Issues and Troubleshooting

Despite their reliability, tranny tubes may encounter issues that require prompt attention and troubleshooting.

Leak Detection and Repair

Address leaks promptly by inspecting connections and fittings, replacing damaged seals, and ensuring proper torque on fasteners.

Overheating Prevention

Monitor transmission fluid temperatures and ensure adequate cooling capacity with properly functioning transmission cooler tubes.

Pressure Management

Troubleshoot pressure buildup issues by checking breather tubes for blockages and ensuring venting pathways are clear.

Future Innovations in Tranny Tube Technology

The future of tranny tube technology promises further advancements in materials, design, and integration within next-generation automotive systems.

Advanced Materials and Composites

Explore the potential of lightweight materials and advanced composites that offer superior heat resistance and durability.

Integration with Smart Systems

Incorporate tranny tubes into smart transmission systems equipped with sensors and adaptive controls for real-time performance optimization.

Eco-Friendly Solutions

Develop tranny tubes that support eco-friendly transmission fluids and sustainable manufacturing practices to reduce environmental impact.

FAQs about Tranny Tubes

What are tranny tubes used for?

Tranny tubes are essential components in vehicle transmission systems, responsible for fluid circulation, cooling, and pressure regulation.

How do I know if my tranny tube needs replacement?

Signs of a failing tranny tube include fluid leaks, overheating transmission fluid, and abnormal transmission operation. Regular inspections and maintenance help identify potential issues early.

Can I upgrade my vehicle’s tranny tubes for better performance?

Yes, upgrading to custom tranny tubes designed for performance can enhance fluid dynamics, heat dissipation, and overall transmission efficiency, particularly in high-performance vehicles.

Are tranny tubes difficult to install?

Installing tranny tubes requires basic mechanical skills and adherence to manufacturer instructions. Professional installation ensures proper fitment and functionality.

Conclusion

Tranny tubes represent a critical link in the chain of automotive transmission systems, providing essential functions that contribute to vehicle performance, reliability, and longevity. This comprehensive guide has explored the various aspects of tranny tubes, from their historical evolution and types to their applications, benefits, and future innovations.

By offering insights beyond conventional summaries, this article aims to serve as a definitive resource for automotive enthusiasts and professionals in the USA, ensuring a deep understanding of tranny tubes and their pivotal role in modern vehicle technology. Whether you’re seeking to optimize performance or maintain reliable transmission operation, choosing the right tranny tube is key to unlocking peak automotive performance and efficiency.